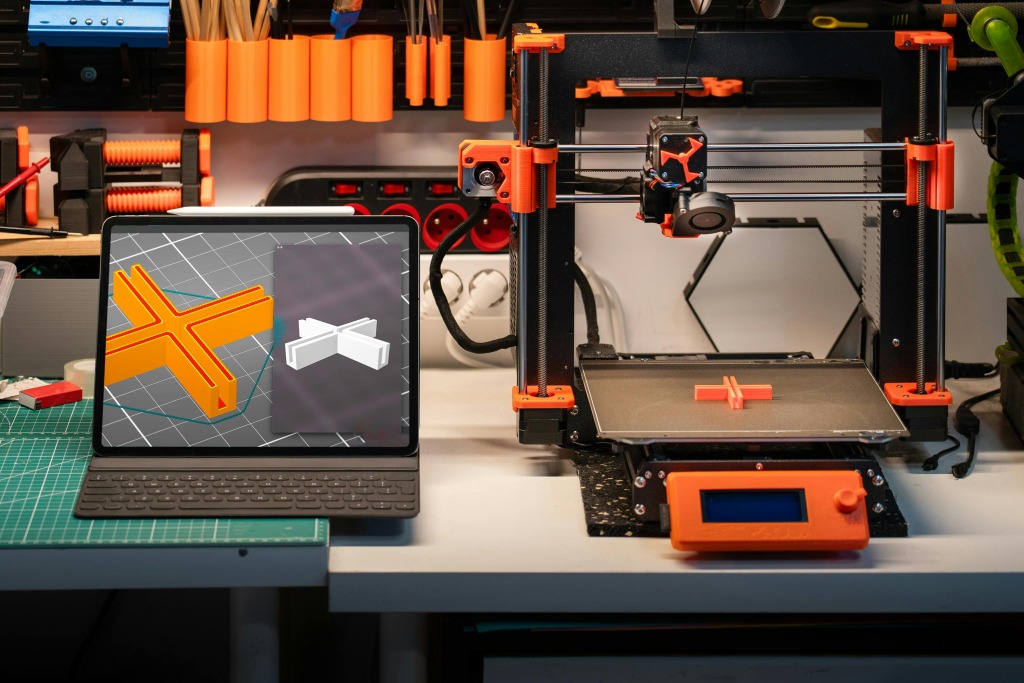

Additive manufacturing or 3D printing is on the rise, continually improving every year thanks to various technological breakthroughs. From aerospace to architecture to healthcare all the way to custom art, additive manufacturing is quite literally reshaping the way we design and produce products in virtually all industries, and there is no indication of it slowing down.

From bioprinting, which holds immense promise for the future of medicine, to metal additive manufacturing, which is bound to transform not only aerospace and architecture sectors, but also the way we produce electronics and various lifestyle products, here are five game-changing technologies that are pushing the boundaries of what’s possible in 3D printing. On a lighter note,

Bioprinting

3D bioprinting, the tissue-engineered technology, is not new – in fact, it’s been used in medicine for nearly 20 years now. Since it can replicate human parts such as tissues, skin, and bones, it’s been used primarily for drug research and testing.

But recently, bioprinting has also been used to repair damaged joints and ligaments. At Pennsylvania State University, biological engineers are working on bioprinting that can create cartilage and bone so they can fix “whatever section of the body needs to be fixed,” including knees, says Nature.com.

Indeed, the future of bioprinting looks as bright as the sun. In the not-so-distant future (a few decades at most), we expect bioprinting to also fix the shortage of donor organs. From skin grafts to whole organ transplants, this technology has a very real potential to revolutionize (and we don’t use that word lightly) the treatment of various medical issues.

On a lighter note, even KFC is looking into bioprinting chicken nuggets – the future really is here!

Metal Additive Manufacturing

Metal additive manufacturing, or metal 3D printing, uses a heat source, like a laser, to heat metal in powder or wire form so that it builds durable objects layer by layer. As you can probably imagine, this type of manufacturing offers unprecedented design freedom: never before were we able to manufacture objects from a variety of metal-based materials this quickly and efficiently.

It’s important to note that with metal 3D printing, there is no need to drill and remove material, so the waste is minimal to non-existent.

As a result of the many benefits this technology offers, it has gained traction in industries that need robust and high-performance components, such as aerospace and medicine.

Companies like GE Additive and EOS have pioneered metal 3D printing techniques that enable the production of high-performance parts for critical applications.

Additive Manufacturing Automation

In additive manufacturing, automation plays a crucial role in streamlining the design and production process, which is why we’ve been seeing more and more novel software options and other automation technologies promising to make the whole process easier, faster, and better.

These tools use artificial intelligence (AI) and machine learning algorithms to automate repetitive and often tedious tasks such as design optimization and part orientation. Take TriStar and their Creo Parametric as an example, a computer-aided design (CAD) software designed to enable engineers to create new products more quickly.

This intelligent tool (and other similar solutions) has features like generative design, augmented reality, real-time simulation, IIoT, and more in order to allow engineers to design better products in a faster and more cost-efficient way.

By utilizing the capabilities of PTC Creo and other generative design apps, companies that work with product design can unlock new possibilities in product development and production, cut their costs, and thereby stay ahead of the curve in increasingly competitive markets.

Multi-Material Printing

While traditional 3D printers are, in and of themselves, pretty impressive, they are also limited to printing with a single material at a time. Thankfully, advancements in multi-material printing technology have opened up new possibilities for creating much more complex and multi-functional objects.

But what exactly is multi-material printing? As the name suggests, this 3D printing uses several different materials in one printing process (source). Bear in mind that this is not the same as multi-color printing; no, multi-material printing uses multiple materials in order to achieve a combination of their properties.

The goal, of course, is to enhance product performance and functionality, or even to create entirely new products. For example, flexible elastomers can be combined with rigid plastics to create custom grips and seals.

Already, we have companies like Ultimaker and MakerBot offering multi-material printing solutions.

Continuous Liquid Interface Production

Continuous Liquid Interface Production, or CLIP for short, is a 3D printing technology that uses UV light, oxygen, and liquid resin to create objects quickly, smoothly, and efficiently. Unlike traditional layer-by-layer approaches, CLIP uses a continuous process that allows for significantly faster print speeds and smoother surface finishes.

But the benefits of CLIP extend beyond speed and surface finish. This technology enables the production of complex geometries with intricate details and fine features. It’s also compatible with a wide range of materials, including engineering-grade resins that exhibit exceptional mechanical properties.

The ability to rapidly prototype high-quality parts makes CLIP ideal for industries where time is of the essence, such as automotive and consumer electronics.

All in all, it’s clear that additive manufacturing is evolving at a breakneck pace and will continue to do so in the years to come. In the near future, we expect to see innovation across industries and sectors: from metal additive manufacturing to bioprinting, these game-changing technologies are opening up entirely new opportunities for designers, engineers, and manufacturers alike.

Last Updated: March 14, 2024